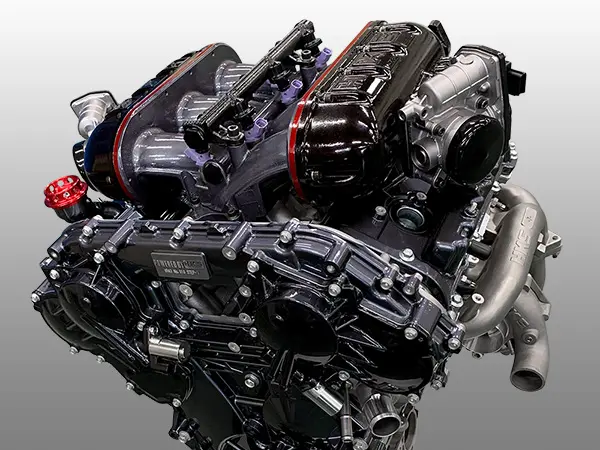

HKS COMPLETE ENGINE VR38DETT 4.3L STEP PRO FOR NISSAN GT-R R35 23011-AN011

Original price was: ¥8,690,000.¥8,678,000Current price is: ¥8,678,000.

Product Code: 23011-AN011

This can be shipped via economy air shipping to most parts of Asia, the US, and Europe. However, the territories cannot be covered with this shipping, we may request an additional shipping charge after the buyer places the order.

Description

The HKS COMPLETE ENGINE VR38DETT 4.3L STEP Pro serves as a purpose-built, fully assembled powerplant. It is engineered specifically for circuit racing applications. Consequently, it delivers enhanced torque capacity, refined responsiveness, and exceptional durability under sustained high-load conditions.

Building directly upon the foundation of HKS’s established 4.3L displacement platform, this complete engine incorporates targeted reinforcements to critical stress points. It also integrates advanced thermal management solutions and precision balancing.

Designed with a primary focus on circuit driving, this engine offers a balanced approach to performance enhancement—providing substantial torque improvements up to 1,500 N·m. It maintains the refined characteristics necessary for consistent lap times and extended track sessions.

Product Highlights

🏁 Circuit-Racing Specific Engineering & Reinforcement

Developed explicitly with circuit racing requirements in mind, this engine features strategic reinforcements to both crankshaft and main bearing cap assemblies. Therefore, it withstands the sustained high-torque loads characteristic of repeated acceleration out of corners and prolonged high-RPM operation. The enhanced torque capacity—targeting up to 1,500 N·m—directly addresses the demands of modern circuit competition. Power delivery consistency proves critical across diverse track conditions.

🔩 Advanced Material Science for Enhanced Durability

Transitioning to nitrided steel for the crankshaft significantly increases surface hardness. It also improves overall material durability under extreme operating conditions. Additionally, the replacement of #2 and #3 journals with chromoly material provides targeted strength enhancement precisely. This is where stress concentrations are highest during circuit driving scenarios.

⚙️ Precision Manufacturing & Tolerancing for Optimal Performance

Incorporating line boring of journal holes ensures exceptional roundness and alignment. Consequently, this minimizes friction losses and promotes optimal oil film maintenance under high-load conditions. Furthermore, the enlargement of crank pin corner radii directly increases torsional strength. This is a critical factor for maintaining power delivery consistency during rapid throttle transitions and gear changes characteristic of circuit driving.

🔥 Comprehensive Thermal Management Architecture

Replacing valve seats with super heat-conductive copper alloy and utilizing phosphor bronze guides dramatically improves valve heat dissipation. As a result, this reduces thermal stress during extended high-RPM operation and helps prevent valve-related failures under sustained circuit racing conditions. This thermal management approach complements the engine’s structural reinforcements to create a comprehensively robust package.

Technical Specifications

Product Name: COMPLETE ENGINE VR38DETT 4.3L STEP Pro

Primary Application Focus: Circuit driving and track-focused competition

Performance & Dimensional Parameters:

-

Expected Torque Capacity: Up to 1,500 N·m (circuit-optimized application)

-

Displacement: 4,255cc (increased 12% over factory 3,799cc)

-

Bore: 95.5mm (maintaining factory bore diameter for compatibility)

-

Stroke: 99.0mm (extended 12% over factory 88.4mm)

-

Compression Ratio: 8.6:1 with 0.8mm metal head gasket

-

Allowable RPM: 7,400 rpm (enhanced 400 rpm over factory limit)

Critical Component Specifications:

Crankshaft & Rotating Assembly:

-

Material: Nitrided steel crankshaft with enlarged fillet radii

-

Bearings: ACL main bearings, genuine connecting rod bearings with WPC treatment

-

Pistons: HKS machined units with molybdenum coating from high-temperature strength A2618 material

-

Connecting Rods: HKS H-cross section design for optimized strength-to-weight ratio

-

Damper: VR43-specific crank damper co-developed with ATI

Cylinder Head & Valvetrain:

-

Seats & Guides: Super heat conductive copper alloy seats with phosphor bronze guides

-

Surface Finish: Step removal and polishing around seats with combustion chamber mirror finishing

-

Camshafts: HKS IN: 270°/11mm lift, EX: 278°/11mm lift

-

Valve Springs: HKS reinforced products with sheet-lapped valves

-

Fastening: ARP reinforced stud bolts with HKS metal head gasket (t=0.8)

Block & Lower End Reinforcement:

-

Targeted Enhancement: #2 & #3 chromoly bearing caps with increased main bearing screw size

-

Precision Machining: Line boring of journal holes combined with honing for optimal cylinder finish

-

Fastening System: HKS M12 stud bolts (625+) for maximum clamping force retention

-

Cover Finish: Baked paint application for durability and aesthetic presentation

Recommended Lubrication: HKS Racing Pro 10W-50 engine oil

Performance & Application Philosophy

Goal: To create a complete, circuit-optimized engine solution that balances increased torque capacity with the refined responsiveness and durability required for consistent lap times and extended track sessions; accordingly, it prioritizes sustained performance over absolute peak power figures.

Focus: Targeted reinforcement of critical stress points identified through circuit racing analysis; comprehensive thermal management for extended high-load operation; precision balancing for smooth high-RPM performance; and integration of proven reliability enhancements that collectively exceed the capabilities of individual component upgrades.

Application & Integration Considerations

⚠️ Critical Usage Parameters & Limitations:

-

Torque Application: 1,500 N·m capacity represents engineering estimates based on internal testing; consequently, actual usable torque will vary with specific vehicle implementation, driving conditions, and supporting system integration

-

Auxiliary System Requirements: Surge tanks, turbines, and other ancillary equipment are not included; therefore, appropriate complementary systems must be selected for optimal performance

-

Professional Installation: Highly recommended given precision tolerances and specialized knowledge required for proper integration

-

Supporting System Calibration: Requires appropriate fueling, ignition, and boost control systems calibrated for circuit-specific operation

🔧 Recommended Complementary Systems:

-

Forced Induction: HKS GTIII-800 or similar circuit-optimized turbo systems

-

Fuel Delivery: HIGH-FLOW SURGE TANK with appropriate injector capacity for sustained high-load operation

-

Cooling: Comprehensive thermal management system including upgraded radiators and oil coolers

-

Management: Track-focused ECU calibration with appropriate data logging and safety parameters

🎯 Primary Performance Characteristics:

-

Circuit-Optimized Torque Delivery: Enhanced mid-range response for acceleration out of corners

-

Extended High-RPM Capability: Reliable operation up to 7,400 rpm for maintaining momentum through longer straights

-

Thermal Consistency: Maintained performance across extended sessions through advanced heat management

-

Balanced Responsiveness: Precision balancing and reduced rotational mass for crisp throttle response

Strategic Advantages & Technical Distinctions

🔄 Circuit-Specific Reinforcement Philosophy

Unlike engines designed for peak power or drag racing, the STEP Pro emphasizes enhancements specifically beneficial for circuit environments; for example, its torsional strength improvements and thermal management directly address the sustained loads and heat buildup characteristic of repeated laps.

⚖️ Balanced Performance Enhancement Approach

Rather than pursuing maximum displacement or compression increases, this engine focuses on balanced improvements across torque delivery, RPM range, and thermal management; consequently, it provides comprehensive circuit performance rather than excelling in a single parameter at the expense of others.

🔍 Targeted Component Enhancement Strategy

The selective reinforcement of #2 and #3 journals and bearing caps demonstrates a sophisticated understanding of VR38 stress patterns under circuit conditions; accordingly, resources are applied precisely where they provide maximum benefit rather than uniformly across all components.

🏎️ Track-Validated Development Methodology

With circuit racing as the explicit design focus, this engine’s development incorporated track testing and validation; therefore, its enhancements address real-world circuit demands rather than theoretical maximums or dyno-focused optimization.

Newly designed, fully machined I-beam connecting rod with 26% improved buckling strength (STEP Pro+ exclusive)

A special oil jet was created using a 3D printer to fit the I-section connecting rod.

Mirror-finished combustion chamber and intake/exhaust ports hand-finished by one of HKS’s most skilled engine builders

Machined piston made from high-temperature strength A2618 material,

with a special two-layer coating for Pro+.

Crank damper exclusively for VR43

(co-developed with ATI)

The crank pin diameter and corner radius have been enlarged to increase the torsional strength of the crank

(enlarged pin diameter is only available on STEP Pro+).

#2 and #3 bearing caps are remade with chromoly material for strength and line boring for improved accuracy

(STEP Pro & STEP Pro+)

Machined I-beam connecting rod bearing

(φ57 STEP Pro+ exclusive)

Exclusive emblem

DLC processed Pro+ exclusive emblem

Dedicated crank:

Asymmetric crank that combines increased strength and reduced inertia weight

Additional information

| OPTION | HIGH-FLOW SURGE TANK R35, HIGH-FLOW SURGE TANK: GT-R (R35), Twin Injector Pro Kit R35 |

|---|

You must be logged in to post a review.

Reviews

There are no reviews yet.