SPOON MONOCOQUE CALIPER SET FOR HONDA S2000 45020-MBR-G00

Original price was: ¥165,000.¥150,000Current price is: ¥150,000.

Part Number: 45020-MBR-G00

![]()

Please select per-product shipping when placing the order. This can be shipped via economy air shipping to most parts of Asia, the US, and Europe. However, the territories cannot be covered with this shipping, we may request an additional shipping charge after the buyer place the order.

Description

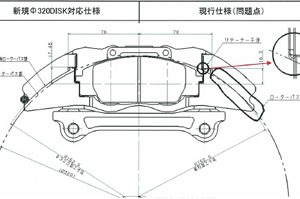

■ Monocoque caliper set Since the opposite caliper can be set to have a higher body rigidity than the embossed type, it has advantages such as lower drag torque value and no pad wear. The monocoque caliper has a monoblock structure and a precision mold casting method. It can be installed with bolts on without any processing and can be used for front and rear brake distribution and ABS as it is. In addition, the pad used is the same shape and size as the genuine S2000, and the rotor size is up to 300 mm and the rotor thickness is up to 26 mm. When installing a monocoque on CL7, DC2, EK9, we have prepared a dedicated brake rotor of 300mm t = 26mm.

| Product No : | 45020-MBR-G00 |

|---|---|

| Price (tax included): | 140,800 yen |

| Applicable model: | S2000 |

| Adaptive model: | AP1-100, AP1-110, AP1-120, AP1-130, AP1-135, AP1-200, AP2-100, AP2-110 |

| Sales unit : | set |

| CODE: CODE: | S |

| Packing weight (Kg): | 7 |

| Packing size: | 28 × 24 × 18 |

| Engine type: | F20C, F22C |

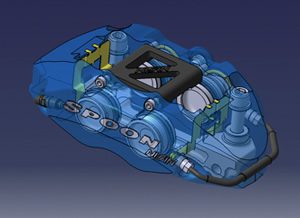

In sports driving, it’s really all about braking. Pressing down on the brake pedal, the nose dives and the driver fights the rear with steering and gas pedal control. Our caliper development focuses on that very moment of excitement. We start by designing the cast. Applying precision aluminum forging technology, the caliper is designed with a 4-piece opposed monocoque structure with variable diameter pistons. The forged caliper support is deeply inserted into the caliper body to securely embrace the hub knuckle. Such design enhances the overall rigidity, minimizing drag torque and bias-wear of brake pads. As the next corner opens its jaws, the driver can fully commit to the last braking point, making the rear follow his lead. Only after mastering the art of braking, the true sensation of sports driving will be rewarded to the driver. Commitment to the true essence of driving. That is where all begins with Spoon.

Validness of the rotor diameter and thermal accumulation

The caliper spec is determined by the rotor diameter and thickness (thermal accumulation). Rotor size is dependent on rim size. At Spoon, we’ve developed twin-block calipers for 15-inch rims and monocoque calipers for 16-inch rims. Here, we will explain the technology behind our monocoque calipers.

Purposive caliper body design and

structure

The caliper features a forged aluminum body offer-

ing minimal weight, plus freedom in design using

purpose-built secondary fabrication equipment. The

variable diameter pistons placed in opposed position

delivers balanced pad pressure. We exposed the

calipers to extensive testing to detect the slightest

change in brake fluid pressure and minimizing the

knock-back amount of caliper pistons, all for the

sake of improving brake performance.

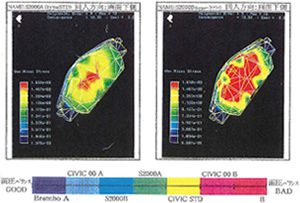

Analyzing variable diameter

caliper pistons

By means of stress analysis, we can derive the

optimum surface pressure distribution on the brake

pads. Incorporating such data, we were able to

minimize bias-wear and balance the pressure on

the pad surface. Parallel to such desk-top analy-

sis, we spent time participating in the Nurburgring

24 hour races and other enduro venues. From

there, we gathered valuable real-life data and

experience that was essential to our R&D.

You must be logged in to post a review.

Reviews

There are no reviews yet.